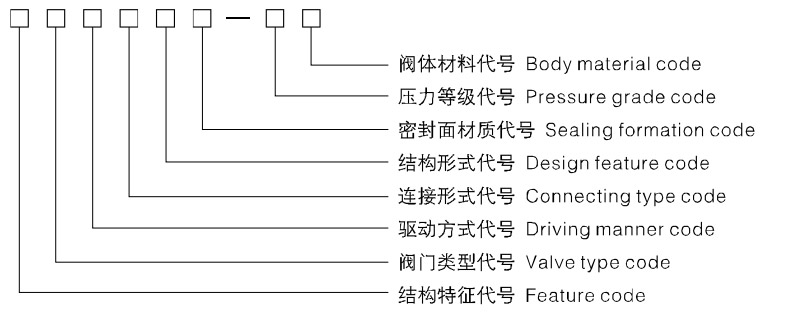

●Feature code: Body, bonnet bolt-jointed structure (default) Hs-body, bonnet welded structure Ps-pressure sealed structure

FL-Reduce expenditure and put emptily T-The valve is one set of types(valve one) K-Antisulphur model

●Valve type code:J-Globe valve

●Driving manner code: 4--Spur gear transmission 5-Bevel gear transmission 6-Air driving 6s-Take pneumatically manually

7-Hydrodynamic driving 9-Electric driving 9B--Explosion electric driving (Hand wheel driving omitted)

●Connecting type code:1-Interior whorl 2--Other whorl 4-Flange 6-Welding 8-Bear and insert welding

●Design feature code:1—Straight general formula 4—Angle type

●Sealing formation code:Y—Hard alloy H—Alloy steel D-Nitriding steel F—Intensified polytetrafluoroethylene(PTPE) X-Rubber

●Pressure grade code: The 10 times of the nominal pressure MPa, pound grade io practical number

●R-CF8M、ZG1Cr18Ni12Mo2Ti S-CF3 L-CF3M F-LCB N-LC3

●Body material code: (1) Cast the valve body: C-WCB I-WC6、ZG1Cr5Mo V-WC9、ZG20CrMoV P—CF8、ZG1Cr18Ni9Ti

R-CF8M、ZG1Cr18Ni12Mo2Ti S-CF3 L-CF3M F—LCB N—LC3

(2) Forge the valve body: C-A105 E-LF2 A-F11 V-F22 P—F304 R-F316 S-F304L L-F316L

Globe valve are used to cut or connect the pipe media under nominal pressure between PN1.6~16.0MPa(Class150~2500), working temperatures <600℃.in oilindustry, chemical industry,pharmaceuticals,fertilizer,and power industry.

The main structure features include:

1. Rational structure, reliable sealing, excellent performance, pretty appearance.

2. Co-radix alloy welded sealing surface, anti-wearing, erosion-proof abrasion-proof and longer use life.

3.The surface and the adjusting media of the valve shaft are nitrogenized so that it is erosion and abrasion resistant.

4. PN>25.0MPa (class15oo), the middle cavity uses a self-tightening sealing structure to have the sealing performance reinforced along with the pressure rise so as to ensure the sealing performance.

5. There is no backward sealing structure in the valve, so the sealing id reliable.

6. The material of the filling and the flange size can be chosen and matched according to the applications and the requirements of the use's. That can satisfies all kinds of working requirements.

| Serial models | (Hs、Ps)J11H、(Hs、Ps)J11Y、(Ps)J41H、(Ps)J41Y、(Ps)J541H、(Ps)J541Y、(Ps)J941H、(Ps)J941Y (Ps)J61H、(Ps)J61Y、(Ps)J561H、(Ps)J561Y、(Ps)J961H、(Ps)J961Y |

||

| Pressure grade range | PN1.6~42.0MPa (Class150~2500) | ||

| Drift diameter range | DN15~400mm(¹/₂"~16") | ||

| Driving manner | Hand wheel driving | Gear driving and electric driving | |

| Scope of application | Class150~300 (PN1.6~2.5) |

Class400~900 (PN6.4~16.0) |

¹/₂"~16" (DN15~400mm) |

| ¹/₂"~12" (DN15~300mm) |

¹/₂"~16" (DN15~400mm) |

||

| Pressure | Testing pressure at constant temperature (Mpa) | Applicable temperature | Applicable medium | |||

| The shell testing | The left sealing | Have and seal testing | ||||

| (MPa) Nominal rating pressure (PN) |

1.6 | 2.4 | 1.76 | 1.76 | -196~600℃ | Water, oil, steam,etc. |

| 2.5 | 3.75 | 2.75 | 2.75 | |||

| 4.0 | 6.0 | 4.4 | 4.4 | |||

| 6.4 | 9.6 | 7.04 | 7.04 | |||

| 10.0 | 15.0 | 11.0 | 11.0 | |||

| 16.0 | 24.0 | 17.6 | 17.6 | |||

| 25.0 | 37.5 | 27.5 | 27.5 | |||

| (Lb) Pound grade (Class) |

150 | 3.0 | 2.2 | 2.2 | ||

| 300 | 7.5 | 5.5 | 5.5 | |||

| 600 | 15.0 | 11.0 | 11.0 | |||

| 900 | 22.5 | 16.5 | 16.5 | |||

| 1500 | 37.5 | 27.5 | 27.5 | |||

| 2500 | 63.0 | 46.2 | 46.2 | |||

| Structural formation | Bolt-jointed bonnet outside stem yoke structure |

| Driving manner | Hand-operated, Electric-driving |

| Design standard | GB/T 12235 |

| Face to face | GB/T 12221 |

| Flanged ends | GB/T 9113、JB/T 79、HG20592 |

| Test & inspection | GB/T 9092 |

Notes: The sizes of valve connecting flange and butt-welding terminas can be designed according to customer's requirement.

|

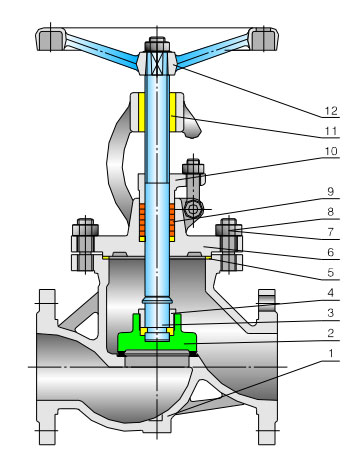

NO. | Part name | Material |

| 1 | Body | WCB、WC1、WC6、WC9、C5 CF8、CF8M、CF8C、CF3、CF3M |

|

| 2 | Disc | 25、1Cr13、2Cr13、1Cr18Ni9Ti、 0Cr18Ni12Mo2Ti、20Cr1Mo1V、25Cr2MoV |

|

| 3 | Stem | 1Cr13、2Cr13、1Cr18Ni9 0Cr18Ni12Mo2Ti、20Cr1Mo1V、25Cr2Mov |

|

| 4 | Flat cover | 25、1Cr13、2Cr13、1Cr18Ni9Ti、 0Cr18Ni12Mo2Ti、20Cr1Mo1V、25Cr2MoV |

|

| 5 | Gasket | Graphite & stainless steel | |

| 6 | Bonnet | WCB、WC1、WC6、WC9、C5 CF8、CF8M、CF8C、CF3、CF3M |

|

| 7 | Stud | 35CrMoA、 0Cr18Ni9、0Cr17Ni12Mo2、25Cr2MoV |

|

| 8 | Nut | 45、35CrMoA、 0Cr18Ni9、0Cr17Ni12Mo2、25Cr2MoV |

|

| 9 | Packing | Graphite | |

| 10 | Packing gland | WCB CF8、CF8M、CF8C、CF3、CF3M |

|

| 11 | Valve stem nut | Copper alloy | |

| 12 | Handwheel | ASTMA47-32510 |

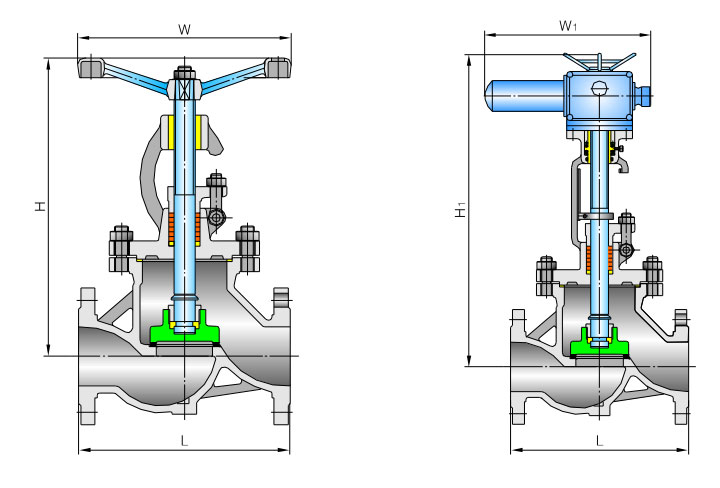

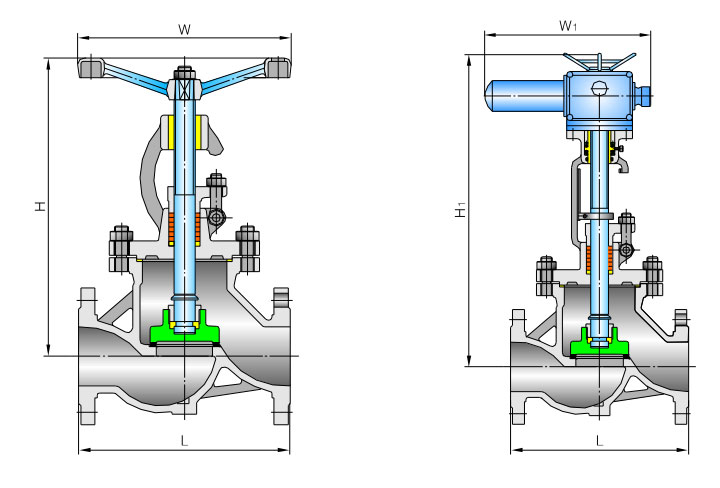

Model: J41H、J41Y、J41W、J41N、J941H、J941Y、J941W、J941N

| Driving | Hand-operated | Electric driving | |||||||

| PN (MPa) |

DN (mm) |

L | H | W | Weight (kg) |

H₁ | W₁ | Electric driving | Weight (kg) |

| 1.6 | 15 | 130 | 218 | 120 | 5.3 | - | - | - | - |

| 20 | 150 | 260 | 140 | 7.2 | - | - | - | - | |

| 25 | 160 | 275 | 160 | 7.5 | - | - | - | - | |

| 32 | 180 | 282 | 180 | 8.7 | - | - | - | - | |

| 40 | 200 | 332 | 200 | 12.4 | - | - | - | - | |

| 50 | 230 | 350 | 240 | 14 | 642 | 960 | DZW10A | 50 | |

| 65 | 290 | 405 | 280 | 22.5 | 695 | 960 | DZW10A | 62 | |

| 80 | 310 | 360 | 280 | 29.5 | 712 | 960 | DZW10A | 65 | |

| 100 | 350 | 412 | 320 | 34 | 772 | 960 | DZW15A | 73 | |

| 125 | 400 | 462 | 360 | 80 | 785 | 960 | DZW20A | 120 | |

| 150 | 480 | 510 | 400 | 95 | 812 | 960 | DZW30A | 212 | |

| 200 | 600 | 715 | 400 | 178 | 965 | 1325 | DZW45A | 325 | |

| 250 | 650 | 789 | 450 | 438 | 1138 | 1325 | DZW60A | 552 | |

| 300 | 750 | 925 | 500 | 650 | 1285 | 1370 | DZW90 | 783 | |

| 2.5 | 15 | 130 | 218 | 120 | 5.5 | - | - | - | - |

| 20 | 150 | 260 | 140 | 7.4 | - | - | - | - | |

| 25 | 160 | 275 | 160 | 7.8 | - | - | - | - | |

| 32 | 180 | 282 | 180 | 8.7 | - | - | - | - | |

| 40 | 200 | 332 | 200 | 12.4 | - | - | - | - | |

| 50 | 230 | 350 | 240 | 15 | 642 | 960 | DZW10A | 52 | |

| 65 | 290 | 405 | 280 | 24.5 | 695 | 960 | DZW10A | 63 | |

| 80 | 310 | 360 | 280 | 31 | 712 | 960 | DZW15A | 68 | |

| 100 | 350 | 412 | 320 | 36 | 772 | 960 | DZW20A | 75 | |

| 125 | 400 | 462 | 360 | 88 | 785 | 960 | DZW30A | 122 | |

| 150 | 480 | 510 | 400 | 98 | 812 | 1325 | DZW45A | 215 | |

| 200 | 600 | 715 | 400 | 183 | 965 | 1325 | DZW60A | 327 | |

| 250 | 650 | 789 | 450 | 443 | 1138 | 1370 | DZW90 | 555 | |

| 300 | 750 | 925 | 500 | 654 | 1285 | 1370 | DZW120 | 786 | |

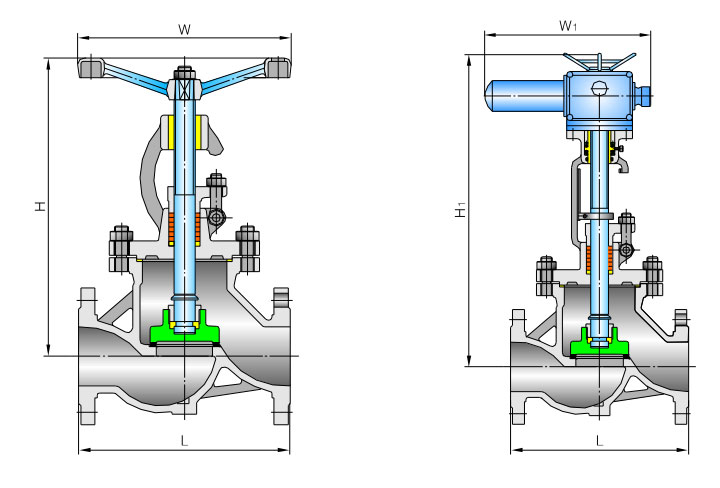

Model: J41H、J41Y、J41W、J41N、J941H、J941Y、J941W、J941N

| Driving | Hand-operated | Electric driving | |||||||

| PN (MPa) |

DN (mm) |

L | H | W | Weight (kg) |

H₁ | W₁ | Electric driving | Weight (kg) |

| 4.0 | 15 | 130 | 235 | 120 | 15.9 | - | - | - | - |

| 20 | 150 | 278 | 140 | 7.5 | - | - | - | - | |

| 25 | 160 | 288 | 160 | 8.0 | - | - | - | - | |

| 32 | 180 | 305 | 180 | 8.9 | - | - | - | - | |

| 40 | 200 | 358 | 200 | 12.5 | - | - | - | - | |

| 50 | 230 | 378 | 240 | 15.2 | 642 | 960 | DZW10A | 61 | |

| 65 | 290 | 408 | 280 | 24.6 | 695 | 960 | DZW10A | 78 | |

| 80 | 310 | 435 | 320 | 32 | 712 | 960 | DZW20A | 85 | |

| 100 | 350 | 482 | 360 | 40 | 772 | 960 | DZW30A | 105 | |

| 125 | 400 | 555 | 400 | 90 | 785 | 1325 | DZW45A | 205 | |

| 150 | 480 | 613 | 400 | 105 | 812 | 1325 | DZW60A | 228 | |

| 200 | 600 | 725 | 400 | 189 | 965 | 1370 | DZW90 | 400 | |

| 6.4 | 15 | 170 | 218 | 140 | 10.2 | - | - | - | - |

| 20 | 190 | 260 | 160 | 13.5 | - | - | - | - | |

| 25 | 210 | 275 | 180 | 15 | - | - | - | - | |

| 32 | 230 | 325 | 200 | 20 | - | - | - | - | |

| 40 | 260 | 360 | 240 | 25 | - | - | - | - | |

| 50 | 300 | 410 | 280 | 36 | 710 | 960 | DZW10A | 65 | |

| 65 | 340 | 450 | 320 | 47 | 752 | 960 | DZW15A | 78 | |

| 80 | 380 | 485 | 360 | 55 | 785 | 960 | DZW30A | 85 | |

| 100 | 430 | 535 | 400 | 123 | 835 | 1325 | DZW45A | 173 | |

| 125 | 500 | 630 | 400 | 130 | 1030 | 1325 | DZW60A | 245 | |

| 150 | 556 | 650 | 450 | 155 | 1065 | 1370 | DZW90 | 300 | |

| 200 | 650 | 810 | 500 | 285 | 1215 | 1370 | DZW120 | 420 | |

Model: J41H、J41Y、J41W、J41N、J941H、J941Y、J941W、J941N

| Driving | Hand-operated | Electric driving | |||||||

| PN (MPa) |

DN (mm) |

L | H | W | Weight (kg) |

H₁ | W₁ | Electric driving | Weight (kg) |

| 10.0 | 15 | 170 | 220 | 120 | 10.5 | - | - | - | - |

| 20 | 190 | 260 | 140 | 14 | - | - | - | - | |

| 25 | 210 | 275 | 160 | 15.5 | - | - | - | - | |

| 32 | 230 | 325 | 180 | 21 | - | - | - | - | |

| 40 | 260 | 360 | 200 | 26.5 | - | - | - | - | |

| 50 | 300 | 415 | 240 | 27 | 715 | 960 | DZW20A | 82 | |

| 65 | 340 | 455 | 280 | 49 | 760 | 960 | DZW30A | 105 | |

| 80 | 380 | 485 | 280 | 56 | 788 | 1325 | DZW45A | 178 | |

| 100 | 430 | 538 | 320 | 125 | 840 | 1325 | DZW60A | 195 | |

| 125 | 500 | 635 | 360 | 134 | 1032 | 1370 | DZW90 | 288 | |

| 150 | 550 | 650 | 400 | 158 | 1072 | 1370 | DZW120 | 450 | |

| 200 | 650 | 812 | 400 | 288 | 1220 | 1395 | DZW180 | 855 | |

| 16.0 | 15 | 170 | 220 | 140 | 12.5 | - | - | - | - |

| 20 | 190 | 262 | 160 | 15.5 | - | - | - | - | |

| 25 | 210 | 275 | 180 | 18 | - | - | - | - | |

| 32 | 230 | 326 | 200 | 22 | - | - | - | - | |

| 40 | 260 | 362 | 240 | 35 | - | - | - | - | |

| 50 | 300 | 417 | 250 | 53 | 745 | 960 | DZW30A | 95 | |

| 65 | 340 | 455 | 320 | 72 | 825 | 1325 | DZW45A | 165 | |

| 80 | 380 | 485 | 400 | 101 | 940 | 1370 | DZW90 | 220 | |

| 100 | 430 | 540 | 450 | 120 | 1152 | 1370 | DZW120 | 240 | |

| 125 | 500 | - | - | - | 1185 | 1435 | DZW180 | 500 | |

| 150 | 550 | - | - | - | 1230 | 1435 | DZW250 | 678 | |

| 200 | 650 | - | - | - | 1500 | 1785 | DZW350 | 1125 | |

The increasing popularity of IoT devices has driven the demand for industrial valves. The integration of IoT sensors in industrial valves enables real-time monitorin...

A gate valve is an opening and closing component, and its movement direction is perpendicular to the fluid direction. A gate valve can only be fully opened and fully...

Ball valve, the opening and closing element (ball) is driven by the valve stem and rotates around the axis of the ball valve. It can also be used for fluid regulatio...